-

Integrating casting and machining processes into its manufacturing, as well as other additional processes which supply parts completed in accordance with the customer’s requirements..

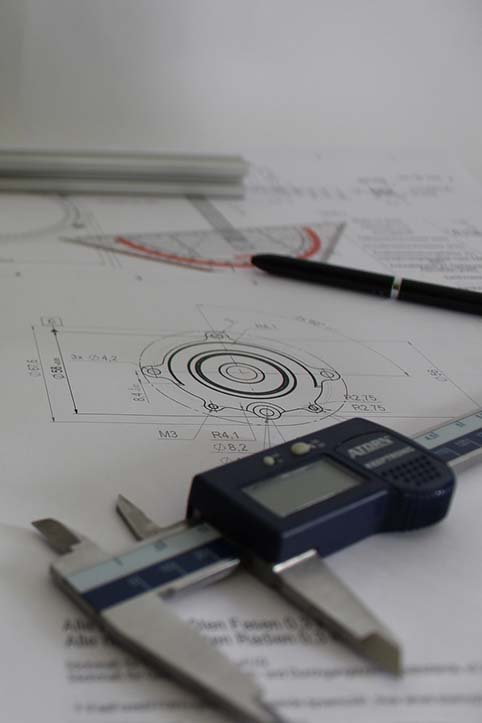

Engineering

With a technical department that collaborates with cutting edge technology centres in casting and machining, the project managers at Metal Group lead, assess and guide customers to optimise and develop their products, from the point of conception for the part, right up until the prototypes and final series are delivered.

Tooling

Thanks to its strategic partner collaborations, Metal Group develops tools that are highly reliable in terms of dimensions and durability, based on the needs of its customers and the sectors they target.

Metal Group manages and takes charge of all phases of the design process, right up to the presentation of samples.

Surface treatment

To meet the most demanding requirements of its customers, Metal Group offers a wide range of surface protection and coating solutions in collaboration with its strategic partners. We can apply coatings to untreated parts, machined parts or parts already assembled in a subset, depending on the process.

Heat Treatment

To meet the most demanding requirements of its customers, Metal Group offers a wide range of surface protection and coating solutions in collaboration with its strategic partners. We can apply coatings to untreated parts, machined parts or parts already assembled in a subset, depending on the process.

Assembly and assembled sets

Metal Group offers its customers solutions for assembly and pre-assembly of various units, prior to the final assembly of the parts.

Part stamping

More tan 20 years of experience in stamping, die-cutting and welding of parts for heavy-vehicles based on customers´ drawings.

Process management from die-design to part dimensional control.